Textile Technologies – machinery, solutions and comprehensive service portfolio for textile manufacturing in Vietnam

From fibre production to the finished fabric – ILLIES ENGINEERING VIETNAM is the only partner of Vietnam’s Textile Industry offering solutions and equipment along the complete textile chain. We offer machinery, solutions and a comprehensive service portfolio including Installation, Repair and After Sales Service for the following processes in textile manufacturing:

- Man Made Fiber

- Spun Yarn Spinning

- Weaving Preparation

- Weaving

- Circular Knitting

- Warp Knitting

- Dyeing

- Finishing

For almost 100 years ILLIES has been establishing longstanding partnerships with leading European textile machinery manufacturers, successfully representing them in various Asian markets. Since the late 1950s, we have been a reliable partner to Vietnamese textile manufacturers. For the Vietnamese market we offer premium machinery & technology from Karl Mayer, Rieter, Oerlikon Barmag, Oerlikon Neumag, Graf, itema, Terrot & Thies.

This portfolio is completed by a highly qualified service station in Ho Chi Minh City including spare parts storage, training facilities and electronic and mechanical repair facilities for local and immediate repairs. The central pillar of this facility is a dedicated team of 40 service specialists focused on customer needs.

ILLIES ENGINEERING VIETNAM is your specialist for any textile application from mosquito nets, to advanced elastic sportswear, up to technical textiles.

Open the following menus to explore our range of technological solutions for textile manufacturing processes in Vietnam:

Our technological solutions for market-specific processes for textile manufacturing:

Man Made Fibers

Machinery for the production of man made fibres. Including the entire process from the core product oil, up to the textile basic product fibre

Man Made Staple Fibers

- Poly Condensation

- Polymer transfer & Extruder

- Spinning

- BCF

- Drawing

- Laboratory equipment

- Cutter & Crimper

Man Made Filament Fibers

- Poly Condensation

- Spinning

- Texturing (DTY)

- Polymer transfer & extruder

- Take up & winding

- Twisting

Spun Yarn Spinning Systems

Machinery for short-staple fiber spinning

Systems for Fiber Preparation: Perfectly Coordinated Technology from Fiber to Sliver

- VARIOline

- Bale Opener UNIfloc A 12

- Card C 70

Systems for Spinning Preparation: Perfect Sliver Quality at Highest Productivity

- Autoleveler Draw Frame RSB-D 50 and Draw Frame SB-D 50

- Autoleveler Draw Frame RSB-D 26

- Draw Frame SB-D 26

- OMEGAlap E 36

- Comber E 86

- Fully automated roving frame F 38 and semi-automated roving frame F 18

- Fully automated roving frame F 39 and semi-automated roving frame F 19

Systems for Ring Spinning: Energy-Saving and Flexible with the Highest Production Rate and Yarn Quality

- Ring Spinning Machine G 38

- Ring Spinning Machine G 37

- Ring Spinning Machine G 32

Systems for Compact Spinning: Best Fiber Yield, Perfect Yarn Structure

- Compact-Spinning Machine K 48

- Compact-Spinning Machine K 47

- Compact-Spinning Machine K 42

- New EliTe®Compact Spinning System

Systems for Rotor Spinning: Cutting-Edge Technology for Automatic and Semi-Automatic Rotor Spinning

- Rotor Spinning Machine R 66

- Rotor Spinning Machine R 36

Systems for Air-Jet Spinning: Quality and Uniqueness Hand-in-Hand with Optimum Productivity

- Air-Jet Spinning Machine J 26

Systems for Automation: Customized Solutions

- Combing Automation SERVOlap E 26

- Ring and Compact-Spinning Automation SERVOtrail

Rieter Com4® Yarns

Digitization: Rieter digital spinning as the key to success

- ESSENTIAL – Rieter Digital Spinning Suite

- Mill Monitoring System SPIDERweb

- Alert and Cockpit Module

- Uptime

After Sales: Boosting Existing Mill Performance

- Parts

- Modernization Solutions

- Preventive Maintenance Packages

- Customer-Specific Engineering

- Service Equipment

Spun Yarn Spinning Components

Machinery for the processing of natural fibres before the further processing in textile industry

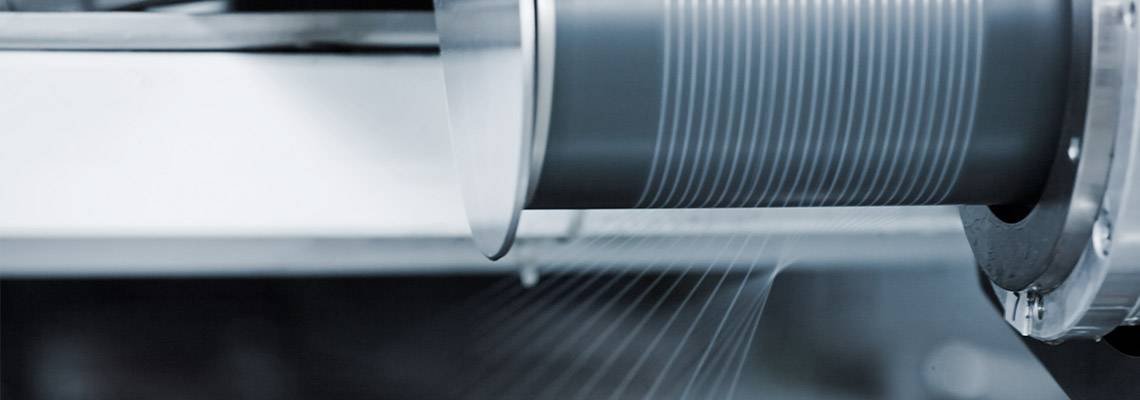

Spinning Preparation: Outstanding quality values at highest production

- GRAF Metallic Card Clothings for the Blow Room

- GRAF Metallic Card Clothings for the Carding

Spinning Preparation: Proven technology paired with innovation for consistently high quality and optimum running characteristics

- GRAF Circular Combs

- GRAF Top Combs

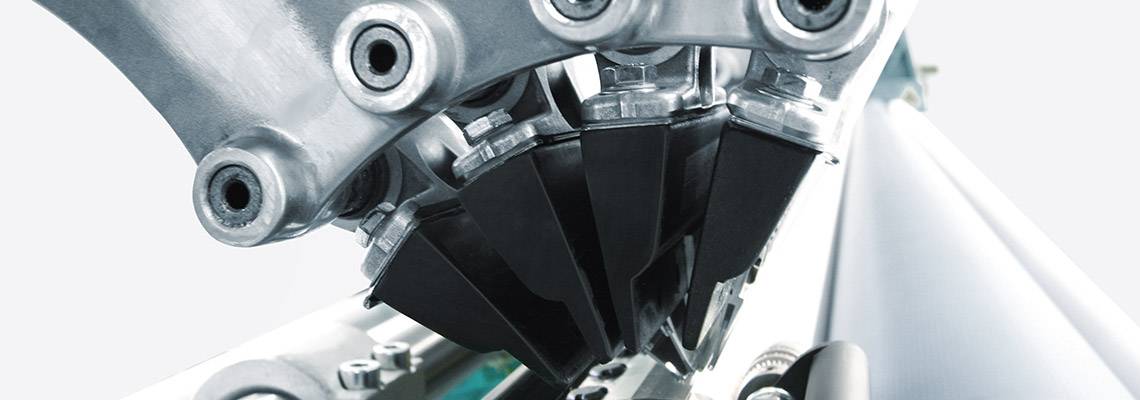

Rotor Spinning: Premium components for original equipment or modernization of rotor spinning machines

- GRAF Clothings for OE Opening Rollers

Nonwoven: Matching clothings are available for roller cards for processing a wide variety of raw materials. The clothing types illustrated represent a selection from our unrivaled large product range.

- GRAF Hipro Metallic Card Clothings

Weaving

Machinery for the further processing of different warp and weft yarn to woven fabrics of diverse types of style

Weaving Preparation

- Creel

- Direct warping

- Sectional warping

- Sample warping

- Beaming / Assembling

- Sizing

- Indigo dyeing (slasher & rope)

Weaving

- Rapier Weaving

- Projectile Weaving

- Air-Jet Weaving

- Weaving Accessories

- Jaquard